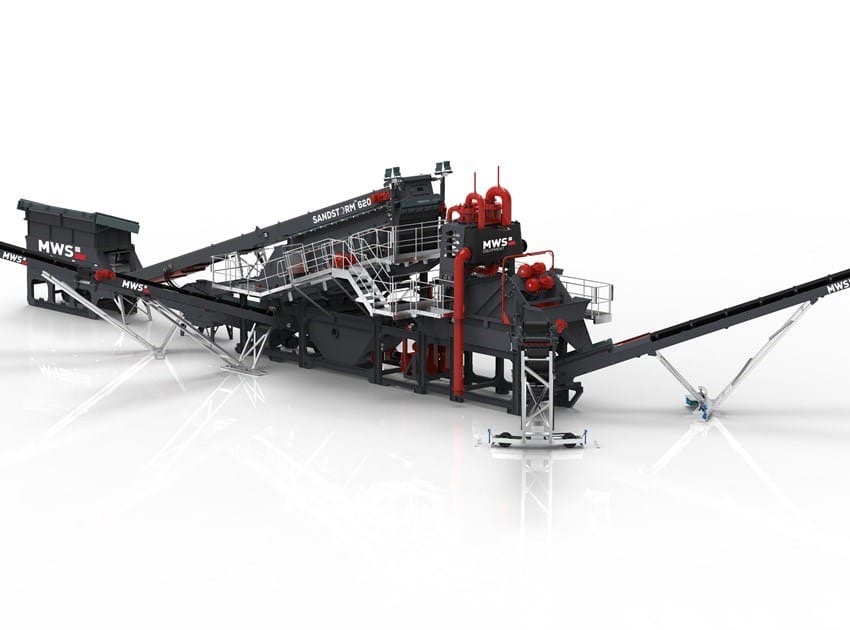

MWS Equipment Modular

The MWS modular products have been designed with absolute focus on the machine operator. In addition to the highest level of quality and performance, significant benefits include simple and fast assembly times, ease of operation, low maintenance and an overall reduced footprint.

The SandstormTM unique design has eliminated spillage of water and materials, creating a clean and safe working environment. Its unique features deliver exceptional results with minimal maintenance required. The MWS AggStormTM range takes washing to the next level by providing robust and reliable equipment for the most challenging applications. The MWS Compact Sand Plant (CSP) range enables superior separation efficiency from the final washed sand product, producing in-spec sands to your desired grade.

- Rubber lined catch boxes and outlet chutes.

- Fully modular chasis structure.

- Remote greasing to all bearings.

- Machines are fitted with an elevated spray bar system.

- Optional dewatering screens, trash screens and aggregate sizing screens.

- Fully containerised for transport.

- Safety panels over shafts and hull.

- Low water consumption.

- Replaceable wear plates on discharge chute.

- Full length galavinised walkways around machine.

- Output up to 120TPH – Single or twin sand.

- High frequency vibrating motors.

- Fully lined discharge chute.

- Rubber lined delivery pipe work and under flow box.

- Self regulated tank level.

- Fully rubber lined cyclones.

- Rubber lined slurry pumps.

- Conical sump design to maximize silt removal from feed material.

- Separator style dewatering cyclone used to optimise silt removal over a wide range of feed material.

- High ware resistance rubber lined split case end suction centrifugal pump.

- Rubber lined sand outlet chute complete with flush water connection.

- Rubber lined anti turbulence feed system.

- Sectional design for ease transport.

- Single or Double sand options.

- up to 3 clean aggregates.

- Radio controlled.

- Advanced automated control system.

- Adjustable feeder and hopper door for consistent material feed.

- 1 Water connection point.

- Radio controlled tipping grid.

- High quality polyurethane scraper.

- Isolated spray bars.

- Full plant LED flood lighting.

- Variable speed belt feeder.

- Small diameter cyclones design to maximise recovery of material 30u and above.

- Designed to reduce the volume of material going to a settling pond or filter press.

- High efficiency recovery of overflow from sand plant.

- Flexibility of design and throughput to match customer demands.

- Various control system option available.