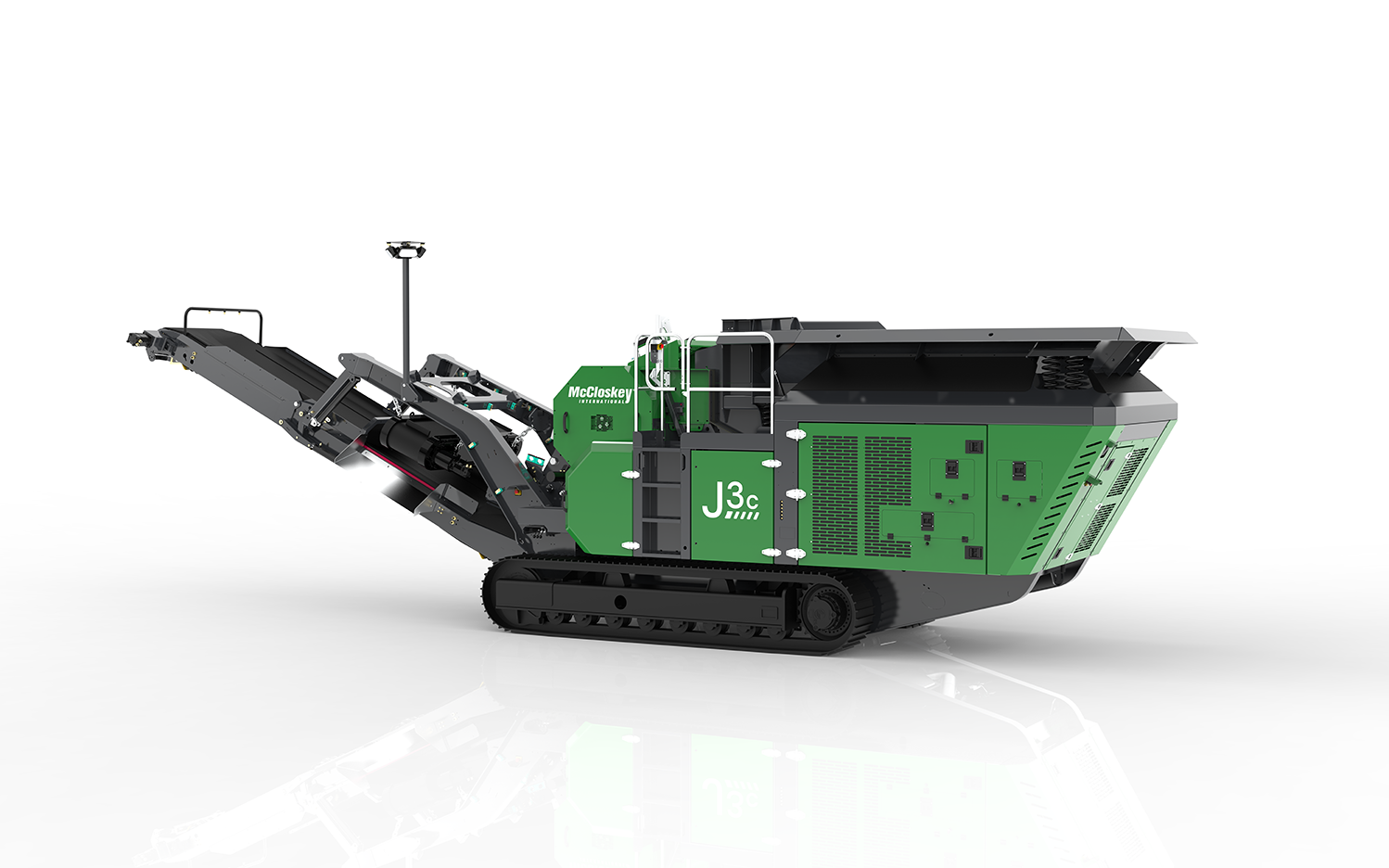

McCloskey Jaw Crushers

With its class-leading throughput and capacity, the Jaw Crusher range brings more power and versatility together to deliver high production.

McCloskey has a proven reputation for designing quality, best-in-class equipment and the jaw crusher range brings more power and versatility together to deliver high production. With its class-leading throughput and capacity and the one of the largest stockpile heights in its category. McCloskey jaw crushers continue to push the boundaries of industry performance. These high capacity jaw crushers have both level and load sensors, a heavy duty bofor design, pan feeder chutes with steeper angles to reduce material sticking, high capacity hoppers and a main conveyor that features easy access heavy duty skirting and ground level access for maintenance.

- 890mm (35″) x 500mm (20″) Jaw Crusher

- Integrated hydraulic folding stockpiling conveyors

- Crawler Tracks.

- 218Hp (162kW) Volvo D5 T3 or T4 Final engine.

- 890mm (35″) wide x 500mm (20″) Jaw Crusher.

- 218Hp (162kW) Volvo D5 T3 or T4 Final engine.

- Double Deck recirculation screen.

- Open chassis design for ease of maintenance.

- Crawler Tracks.

- 218Hp (162kW) Volvo D5 T3 or T4 Final engine.

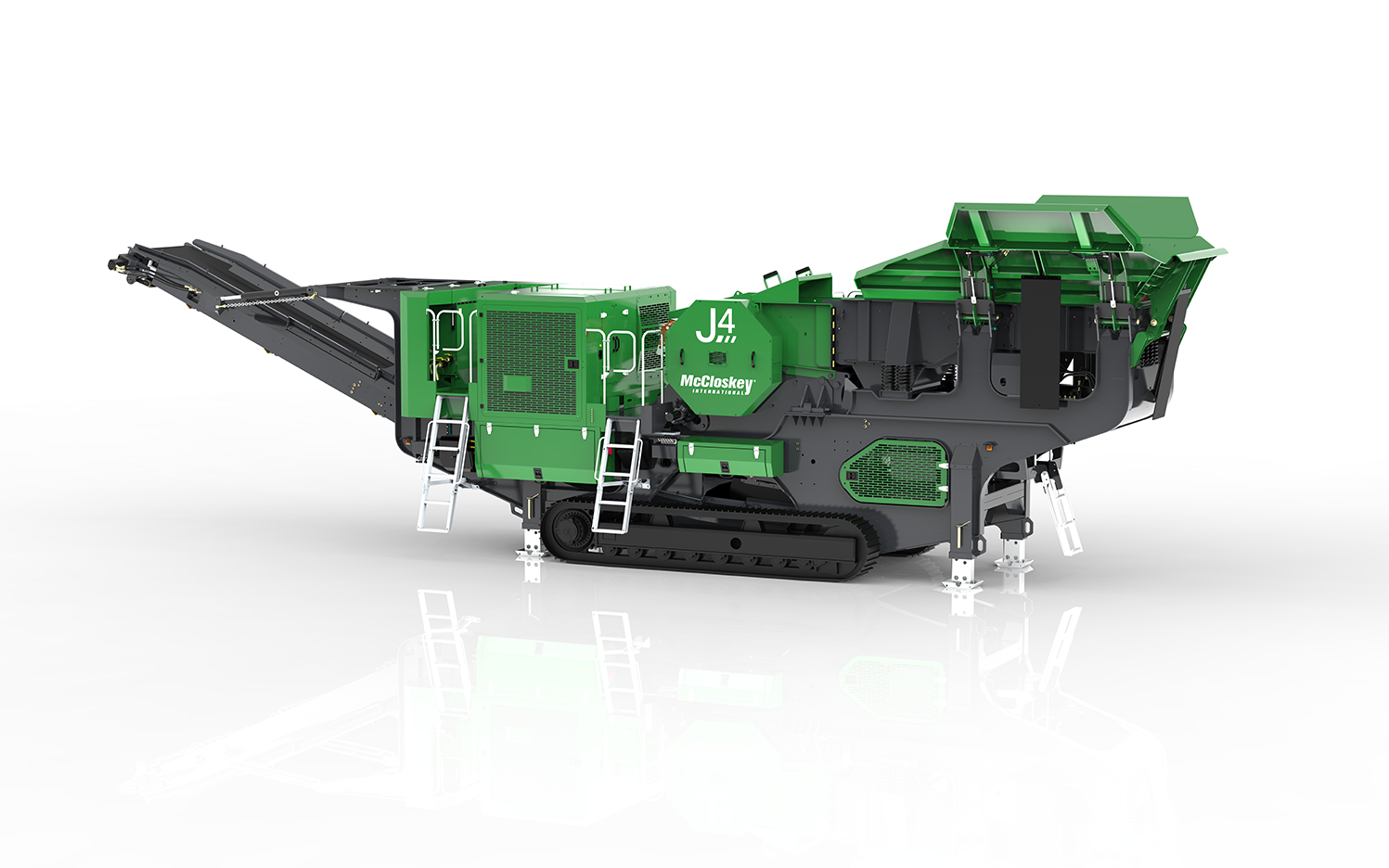

- 1060mm (42″) wide x 700mm (28″) single toggle jaw.

- Choice of CAT or Volvo, LRC or T4F/Stage V engines.

- HD crawler tracks.

- Integrated hydraulic folding hopper.

- Integrated hydraulic folding stockpiling conveyors.

- Large gap between crusher discharge and main conveyor feedboot

- 1016 (40”) x 610 (24”) single toggle jaw.

- CAT Tier 3 option / CAT & Volvo Tier 4F / Stage 5 option

- Tracked

- Integrated hydraulic folding hopper

- Integrated hydraulic folding stockpiling conveyors

- Large gap between crusher discharge and main conveyor feedboot

- 1140 (45”) x 688 (27”) single toggle jaw

- 350Hp C9 / C9.3 Cat engine.

- Integrated hydraulic folding stockpiling conveyors

- I-beam plate fabricated chassis construction

- Track or Track c\w Wheel bogie

- Open chassis design for ease of maintenance

- 1140 (45”) x 688 (27”) single toggle jaw.

- 350Hp C9 / C9.3 Cat engine.

- Double Deck recirculation screen.

- Integrated hydraulic folding stockpiling conveyors.

- Track or Track c\w Wheel bogie.

- 1270 (50”) x 735 (29”) single toggle jaw.

- 375Hp C9 /C9.3B Cat / 361Hp D11 Volvo engine

- Integrated hydraulic folding hopper

- I-beam plate fabricated chassis construction.

- Open chassis design for ease of maintenance

- 1200mm (48″) wide x 864mm (34″) single toggle jaw.

- Choice of CAT or Volvo LRC, Tier 4/Stage 5 engines

- HD crawler tracks.

- Large gap between crusher discharge and main conveyor feedboot

- Integrated hydraulic folding stockpiling conveyors