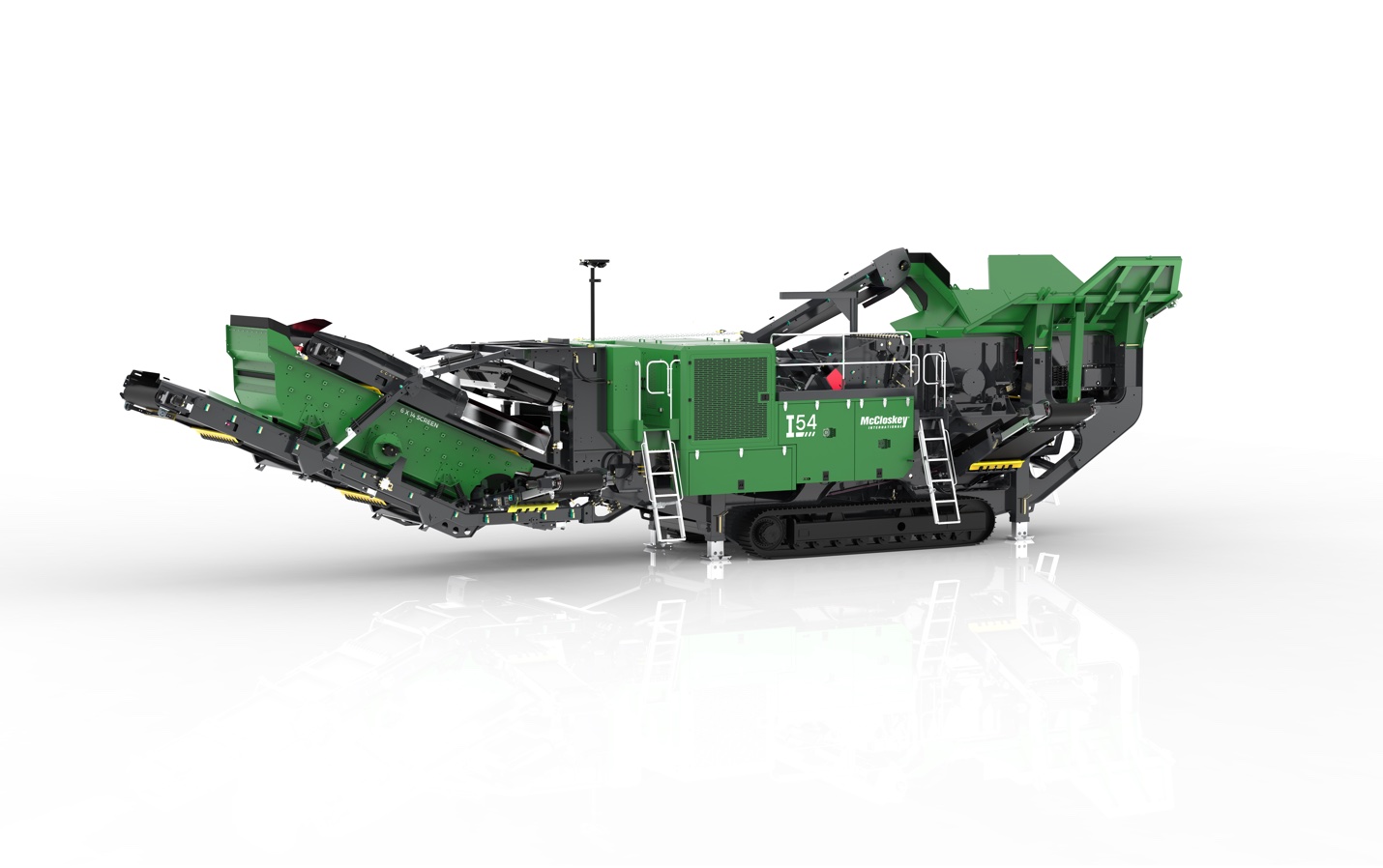

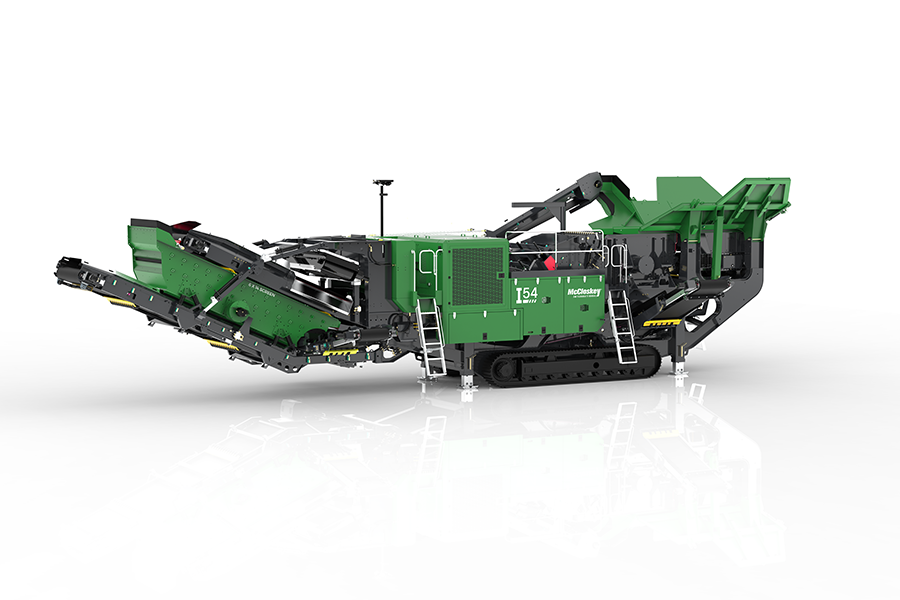

McCloskey Impact Crushers

The Recirculating Impact Crushers offer versatility, allowing operators to produce a crushed and screened final product with one machine. A swing-out radial return conveyor can complete 90 degrees while the machine is running for additional stockpiling.

McCloskey brings high quality and high production capacity to mobile impactor applications. The direct drive crusher boosts power and lowers fuel costs, and along with an optimized material flow path and open chassis for ease of maintenance, boost production and efficiency as well. The Recirculating Impact Crushers offer versatility, allowing operators to produce a crushed and screened final product with one machine. A swing-out radial return conveyor can complete 90 degrees while the machine is running for additional stockpiling. McCloskey impactors are ideal for some of the toughest applications worldwide, including asphalt recycling, concrete recycling, rock crushing, construction and demolition.

- 900mm (35.4″) diameter x 820mm (32.3″) wide Impactor.

- 252Hp (188kW) Volvo D8 T3 or T4 Final engine.

- Integrated hydraulic folding stockpiling conveyors.

- Apron adjustment to suit either Secondary or Primary crushing.

- 900mm (35.4″) diameter x 820mm (32.3″) wide Impactor.

- Integrated hydraulic folding stockpiling conveyors.

- Single Deck recirculation screen.

- Swing out radial return conveyor.

- Open chassis design for ease of maintenance.

- 1050mm (41.3″) diameter x 1125mm (44.3″) wide Impactor.

- 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine.

- Vibrating feeder under crusher discharge.

- 1050mm (41.3″) diameter x 1125mm (44.3″) wide Impactor.

- 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine.

- Vibrating feeder under crusher discharge.

- Single Deck recirculation screen.

- 1050mm (41.3″) diameter x 1125mm (44.3″) wide Impactor.

- I-beam plate fabricated chassis construction.

- Apron adjustment to suit either Secondary or Primary crushing.

- Integrated hydraulic folding stockpiling conveyors.

- 1050mm (41.3″) diameter x 1125mm (44.3″) wide Impactor.

- 375Hp (280kW) CAT LRC or T4/T5 engine.

- Integrated hydraulic folding stockpiling conveyors.

- Single Deck recirculation screen.Crawler Tracks.

- Swing out radial return conveyor.

- 1200mm (48″) diameter x 1350mm (53″) wide Impactor.

- 510Hp (380kW) Volvo D13 Stage V engine/ 516Hp C13 CAT LRC / 536Hp C13 CATStage V.

- Integrated hydraulic folding stockpiling conveyors.

- I-beam plate fabricated chassis construction.

- 1200mm (48″) diameter x 1350mm (53″) wide Impactor.

- 510Hp (380kW) Volvo D13 Stage V engine/ 516Hp C13 CAT LRC / 536Hp C13 CATStage V.

- Single Deck recirculation screen.

- Integrated hydraulic folding stockpiling conveyors.

- I-beam plate fabricated chassis construction.