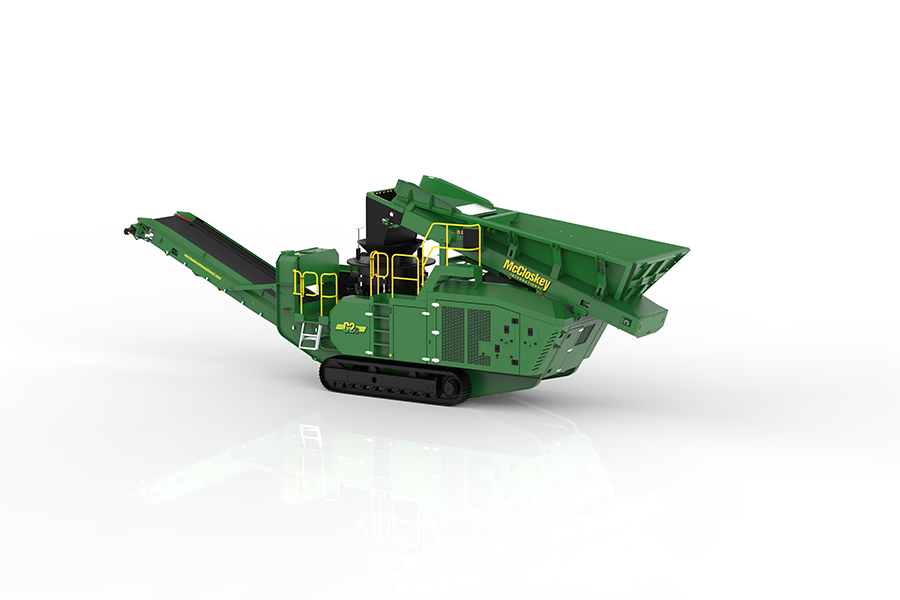

McCloskey Cone Crushers

McCloskey’s mobile Cone Crushers have been designed to deliver superior performance whilst also achieving higher capacity, better product quality, optimum versatility, and improved fuel efficiency.

McCloskey mobile cone crushers have been designed to deliver superior performance whilst also achieving higher capacity, better product quality, optimum versatility, and improved fuel efficiency. Standard features are far from standard on McCloskey crushers, including an open chassis design, efficient conveyor design, recirc screen options as well as continuous load and material level monitoring. From the compact and nimble C2C with a full size MC200 cone to the C3 and C4 cones with their high capacity and throughput, McCloskey cone crushers push the boundaries of industry performance across applications.

- MC200 Cone.

- 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine.

- Tracked.

- Large gap between crusher discharge and main conveyor feedboot.

- Integrated hopper with folding rear door.

- MC300 Cone.

- 510Hp D13 Volvo Penta engine/ 516Hp C13 CAT LRC / 536Hp C13 CAT Stage V.

- Integrated hopper with folding rear door.

- I-beam plate fabricated chassis construction.

- Large gap between crusher discharge and main conveyor feedboot.

- MC300 Cone.

- 510Hp D13 Volvo Stage V engine/ 516Hp C13 CAT LRC / 536Hp C13 CAT Stage V

- Double Deck recirculation screen.

- Tracked.

- I-beam plate fabricated chassis construction.

- Large gap between crusher discharge and main conveyor feedboot.

- MC400 Cone.

- 612Hp D16 Volvo Penta engine.

- Tracked.

- Integrated hopper with folding rear door.

- Large gap between crusher discharge and main conveyor feedboot.

- Open chassis design for ease of maintenance.