Lippmann Jaw Crushers

Designed for strength and dependability in the harshest conditions. Massive, single piece frames are stress-relieved before machining and after welding to ensure the highest quality product. Through finite element analysis, Lippmann engineers have been able to provide jaw crushers with maximum strength at all stress points; promoting trouble-free operation. Coupled with the strength of a one-piece pitman, long reversible jaw dies and steeper nip angle, increased capacity and production are to be expected with Lippmann Jaws.

Wheeled Jaw Plants

Durable, high-production jaw crushers on stout, easy-to-move truck frames.

Combining standard configurations for various applications, with a willingness to develop custom solutions, gives each customer the kind of flexibility that translates into success in the field. Perfecting our legendary jaw plants, they also feature the rugged Lippmann feeder, capable of handling side or rear loading from various types of equipment and multiple discharge conveyor configuration options.

- 20-Ton (18t) hopper constructed of AR steel

- 51” (1295mm) x 20’ (6.10m) Vibrating grizzly feeder with 5; (1.50m) adjustable grizzly

- Adjustable tail section

- 30” (762mm) Gape by 48” (1219mm) wide jaw with opposing wedge design

- One piece steel pitman

- Oversized tapered roller bearings

- 54” (1372mm) Conveyor with CEMA C idlers, premium belt scrapper and extended with hydraulic fold

- Opposing wedge toggle tensioning system

- Spherical roller bearings on the frame

- Oversized roller bearings on the pitman

- Steel Cheek Plates

- -30”x62” Jaw Crusher

- Two heavy duty flywheels one grooved for v-belts

- 62”x18’ Feeder

- Steel check plates

- One piece steel pitman

- Reversible manganese steel jaw dies and extensions

- 48” single toggle jaw c/w 200 HP motor

- Chassis cable hooks

- Heavy duty chassis for semi towing

- 30” cross conveyor for grizzly bars

- Heavy duty 4 axel spring suspension

- Integrated motor mount

- 54” (1372mm) conveyor with CEMA C idlers and premium belt scraper

- Automatic lubrication system

- Manual toggle adjustment

- Oversized tapered roller bearings

- Reversible manganese steel jaw dies and extensions

- Replaceable swing jaw barrel protector

- 62”x24’ Feeder

- One Piece steel pitman

- Manual toggle adjustment

- Heat treated forged alloy steel eccentric shaft

- 42”x48” Jaw Crusher

- Two heavy duty flywheels one grooved for v belts

- Heat treated forged alloy steel eccentric shaft

- Manual toggle adjustment

- 56”x26’ Feeder

- 54” Discharge Conveyor

Tracked Jaw Plants

Delivering a high production jaw with the mobility of tracks.

At the heart of our tracked plants is the Lippmann jaw chamber. It’s a jaw crusher know throughout the industry for its unmatched production and reliability. Combining a stout, torsional resistance chassis design with oversized tracks, Lippmann has created the ideal track-mounted jaw plant. One that provides the high production that is expected from a Lippmann jaw crusher with the ease of movement desired of a track-mounted machine.

- 48” (1200mm) belt with hydraulic adjustable angle for large stockpile capacity

- 1060mm wide x 700mm single toggle jaw

- HD crawler tracks

- Large gap between crusher discharge and main conveyor feedboot

- Open chassis design for ease of maintenance

- Optimized material flow with high TPH

- 12” DSE control panel

- High inertia single toggle 48” x 34” (1200x864mm) jaw with heavy duty bolted construction

- 48” x 34” jaw opening

- High volume fuel tank

- Connected to line power or onboard generator

- Wide main side conveyors

- Large gap between crusher discharge and main conveyor belt

- 48” x 34” jaw opening

- Heavy duty bolt on tracks with smooth start/stop 3-spped system

- 12” DSE control panel

- High volume fuel tank

- 51” x 39” Jaw Opening

- Adjustable conveyor under the crushing chamber

- JF 1250 feeder with 2-step grizzly

- Hopper with chutes lined with wear plates

- Ground level diesel tank access for genset

- Self-regulating front jack legs

- 1140 (45”) x 688 (27”) single toggle jaw

- I- beam plate fabricated chassis construction

- 350 Hp C9/C9.3 CAT engine

- Large gap between crusher discharge and main conveyor feedboot

- Integrated hydraulic folding stockpiling conveyors

- Track or track c/w wheel bogie

- 50”x29” single toggle jaw

- 350 Hp C9/C9.3 CAT engine

- Integrated hydraulic folding hopper

- Open chassis designed for ease of maintenance

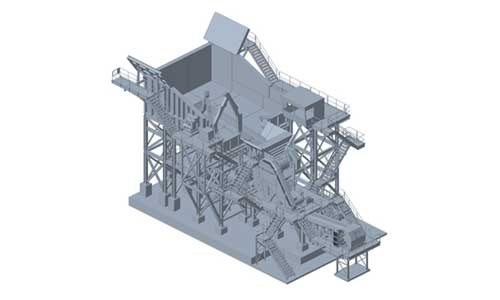

Stationary Jaws

When you compare a Lippmann jaw to others on the market, the difference is clear. Our robust shafts and superior components are engineered for maximum strength and durability, while our heavier frames provide unmatched stability. By integrating these powerful crushers into a stationary rock box structure, Lippmann has perfected the first step in crushing applications.

- Custom plant design

- Application specific designs to ensure 100% customer satisfaction

- Meets and exceeds expectations for performance and production

- Built for demanding production, strength, and a lifetime of dependability

- One piece steel pitman

- Reversible manganese steel jaw dies

- 50” x 62” Jaw crusher

- Replaceable wear plate behind the swing jaw die & stationary jaw die

- Replaceable swing jaw barrel protector

- Longer jaw length to provide increased crushing area

- Inside contact surfaces are fully machined

- Protected pitman hub with rock rib

- Dynamically balanced flywheels reduce vibration