Lippmann Impact Crushers

Proven to be durable, high performance and cost effective solutions in a variety of applications. Lippmann Impact Crushers are designed specifically for demanding aggregate and recycle operations. They are fabricated to provide cost efficient crushing solutions to customers, without losing strength or efficiency. Due to the varying crusher sizes, Lippmann is able to provide a solution to any crushing scenario no matter the size.

Wheeled Impactor Plants

Lippmann’s wheel-mounted impactor plants provide a high-production, cost-effective crusher on a rugged truck frame. These portable plants are equipped with heavy-duty Lippmann grizzly feeders sized for optimal throughput. Plants are customized with various discharge methods including conveyor belts of varying length or vibrating pan feeders. No matter the application, we have the optimum, innovative solution for your specific needs.

- 3 & 4 bat rotor options with crushing chamber improve material flow efficiency

- 6 Hydraulic run-on jack legs

- NEMA 12 motor control center

- One gravity and one spring loaded curtain

- Hydraulically adjustable discharge conveyor angle

- Inspection door on side of machine

- One gravity and one spring loaded curtain

- High ratio of reduction

- I Beam welded steel truck frame with structural cross members

- 48” front discharge conveyor with 3-ply belting

- 51” x 65” horizontal shaft impactor with 40” x66” feed inlet opening

- 51” x 65” horizontal shaft impactor with 40” x 66” feed inlet opening

- Elevated operator’s platform with ladder access from main platform

- High ratio of reduction

- Hammers have four crushing positions to maintain a more consistent gradation & greater top size control

- No weld build up required

- Andreas type impact crusher design

- Inspection door on side of the machine

- High ratio of reduction

- Hammers have four crushing positions to maintain a more consistent gradation & greater top size control

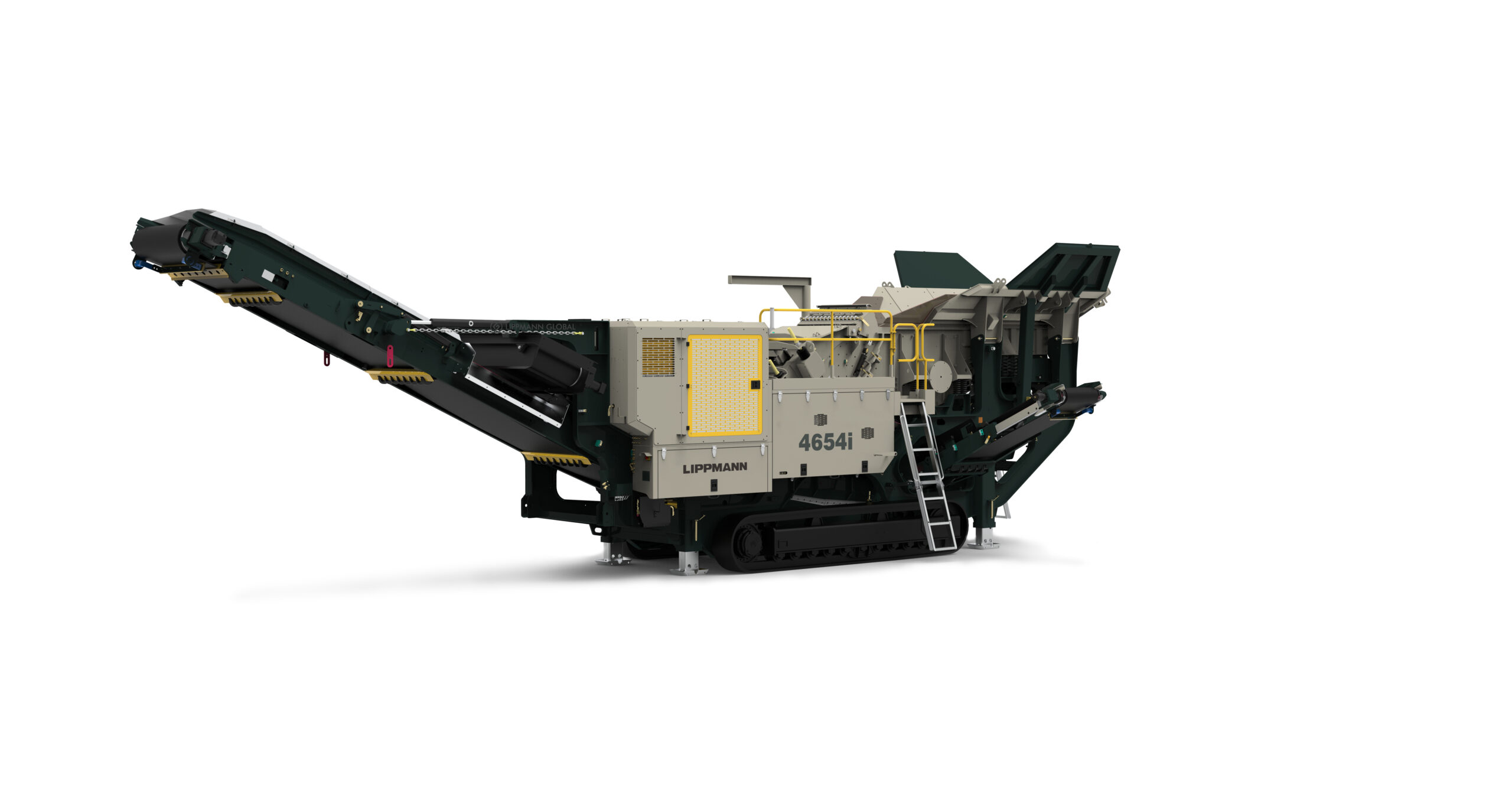

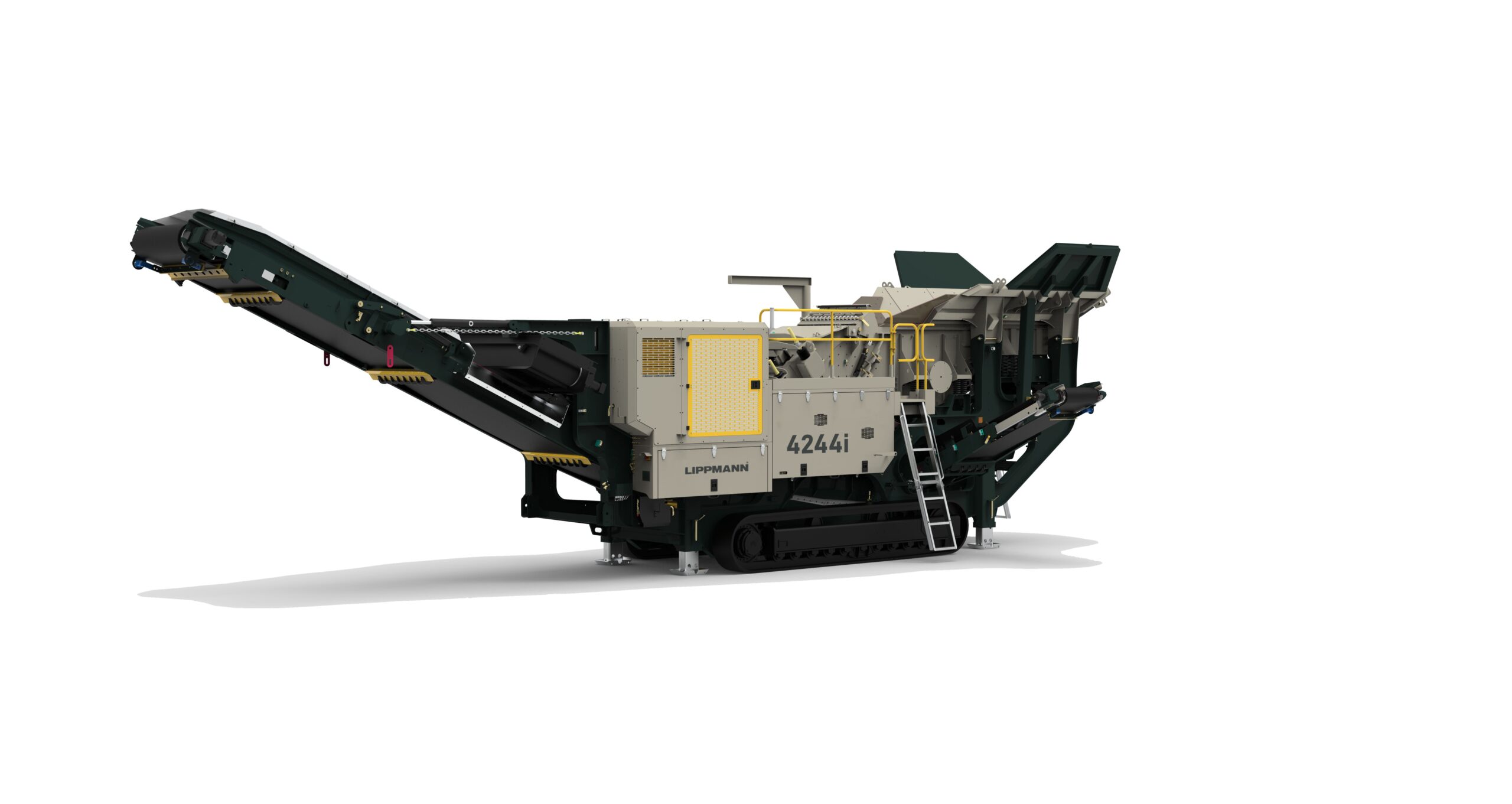

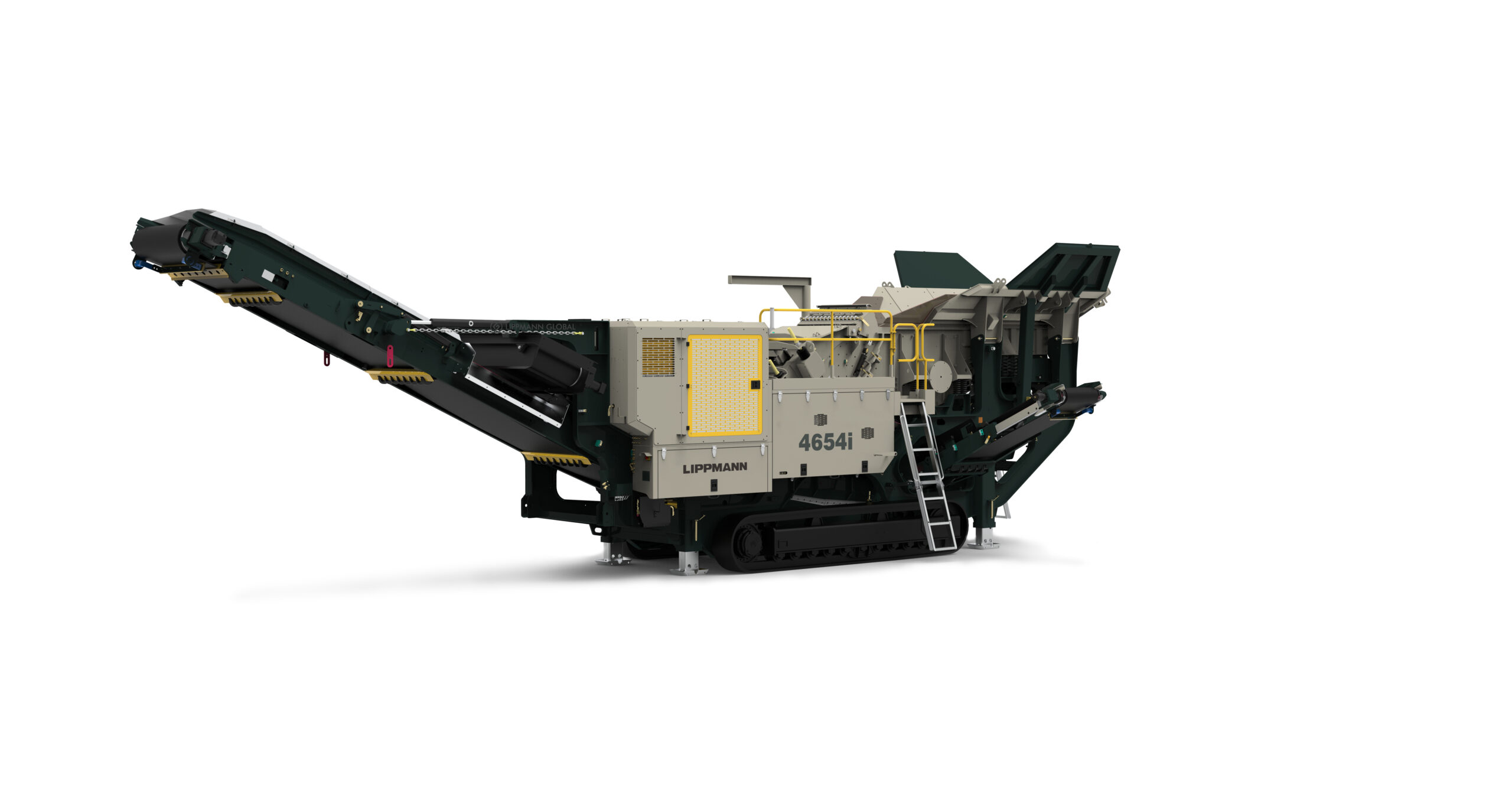

Tracked Impactor Plants

Lippmann tracked impact crushers are built to excel in the toughest aggregate, mining, and recycling applications. Proven across a wide range of materials such as limestone, dolomite, gravel, basalt, copper reverts, concrete, and asphalt, these crushers maintain exceptional strength and efficiency throughout. Whether in challenging terrains or critical crushing scenarios, our tracked units deliver consistently high production and value. Equipped with Lippmann grizzly feeders and engineered for optimal throughput, these rugged machines are designed to meet the demands of any job site, providing flexibility and power in a mobile format.

- 41.3” (1050mm) diameter x 44.3” (1125mm) wide impactor

- I beam plate fabricated chassis construction

- Vibrating feeder under crusher discharge

- 360 Hp Volvo D11 T4 final engine or 350Hp CAT 9 Tier 3 engine

- Open chassis design for ease of maintenance

- 3660mm x 1525mm (12’x5’) double deck recirculation screen

- Vibrating feeder under crusher discharge

- 360 hp Volvo D11 T4 Final engine or 350hp CAT C9 Tier 3 engine

- Integrated hydraulic folding hopper

- 1050mm (41.3”) diameter x 1125mm (44.3”) wide impactor

- External belt alignment points

- Full safety guarding for nip points

- Various blow bar materials options

- Hopper extensions

- External grease points

Stationary Impactors

Proven in a variety of applications and materials, Lippmann stationary impact crushers stand up to the most demanding aggregate, mining and recycling operations. These rugged impact crushers provide consistent high production at an incredible value. For optimal throughput, impact crushers are engineered for your most critical crushing scenarios.

- Andreas type impact crusher design

- Produces highly cubical product

- High ratio of reduction

- Less capital outlay than competitive crushers

- Wear components have long life due to advanced metallurgy