Lippmann Cone Crushers

Lippmann cone crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of application suitability. From limestone to aconite, from ballast production to manufactured sand, and from small portable plants, cone crushers provide unbeatable performance in secondary, tertiary, and quaternary applications.

Wheeled Cone Plants

Our cone crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of application suitability. From limestone to aconite, from ballast production to manufactured sand, and from small portable plants, cone crushers provide unbeatable performance in secondary, tertiary, and quaternary applications.

- Lockable 8hp electric start Honda Powered hydraulic power pack

- 6x drop down crib legs

- Overflow chute & storage for transport

- 8.31” (211mm) Feed opening

- Full length wheel fenders

- 300 hp electric driven cone crusher

- 5’ x 20’ (1524 x 6100mm) 3-deck incline screen

- Top two decks feed cone or top deck feeds cone and mid deck to chute on cone feed conveyor side

- Variable speed feeder

- 370ft3 (10m3) hopper/feeder capacity

- 36” (914mm) feed conveyor with swing capabilities

- 400 Hp 1200 RPM (298kW 20Hz)

- Large walkways for easy access to crusher and auxiliary items

- Overflow chute

- 42” (1067mm) rear discharge conveyor

- Bushing type cone with superior speed throw and cavity design

- 500Hp 1200 RPM (355kW 20Hz)

- Large walkways for easy access to crusher and auxiliary items

- 54” (1372mm) rear discharge conveyor

- (6) run-on jack legs

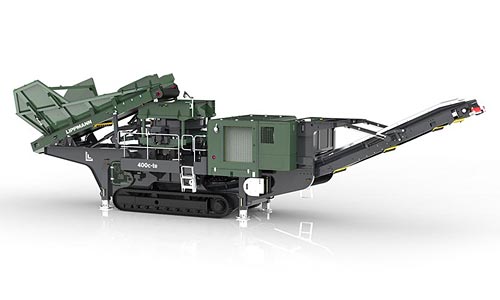

Tracked Crushers

Lippmann heavy duty tracked cone crushers feature an innovative material flow that maximizes capacity and throughput while delivering a consistently high-quality product. The tracks enhance the job site mobility of this crusher, ideal for any spread.

- Integrated hopper with folding rear door

- Large gap between crusher discharge and min conveyor feedboot

- 41” (1050mm) Feed Opening

- Fast set up time

- 612 Hp D16 Volvo Penta Engine

- I beam plate fabricated chassis construction

- Open chassis design for ease of maintenance

- Large gap between crusher discharge and main conveyor feedboot

- Integrated hopper with folding door

- Tracked mobility

- Integrated hopper with folding rear door

- 700Hp C18 Cat LRC engine or 751 Hp C18 CAT stage V

- Engine safety shutdown systems

- External grease points